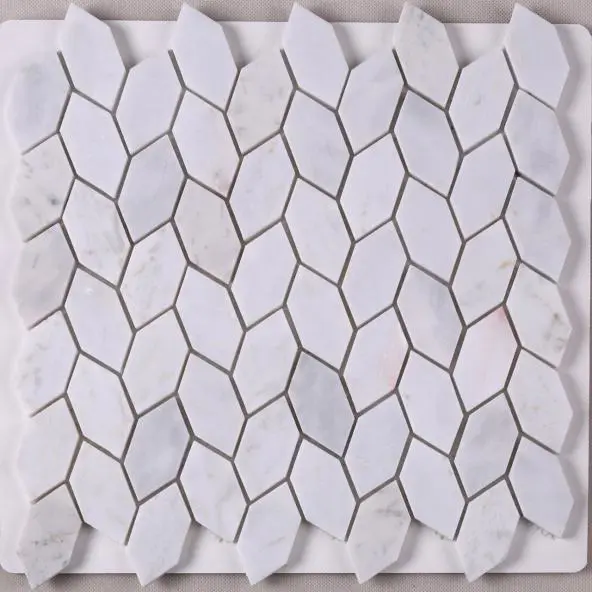

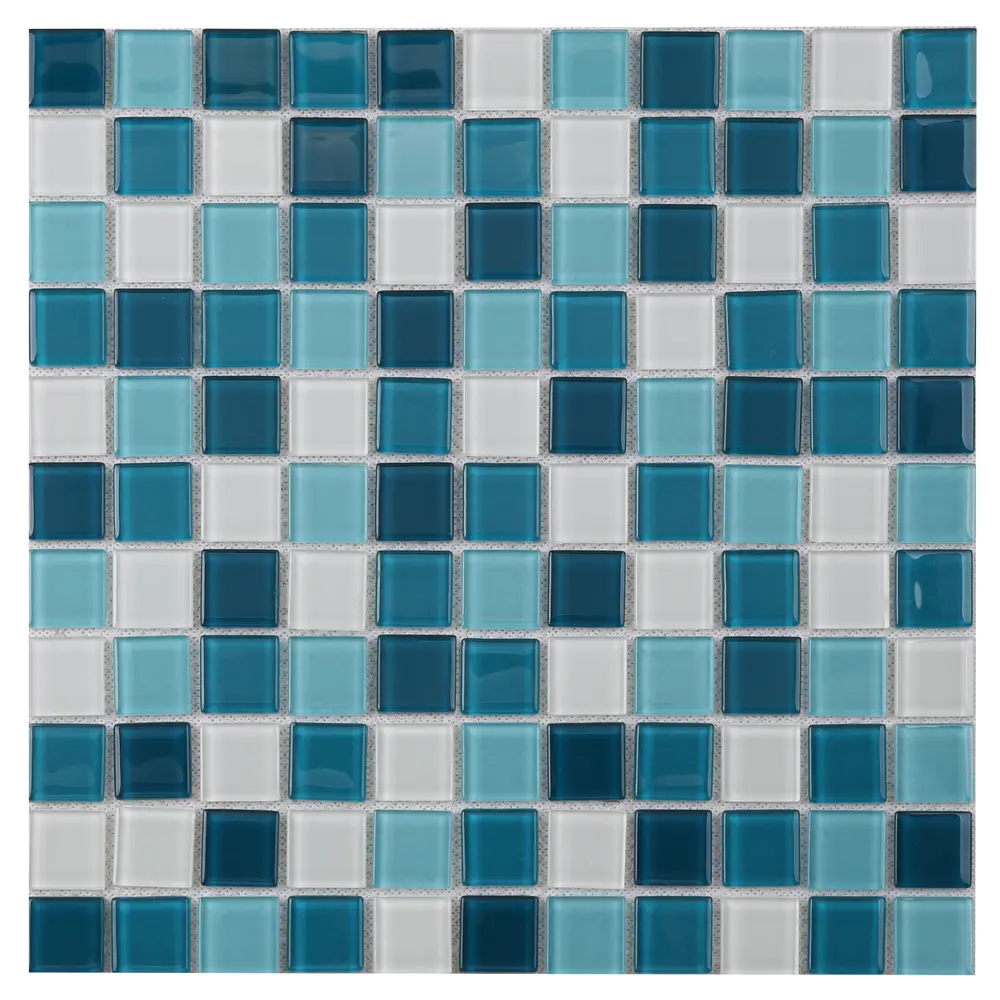

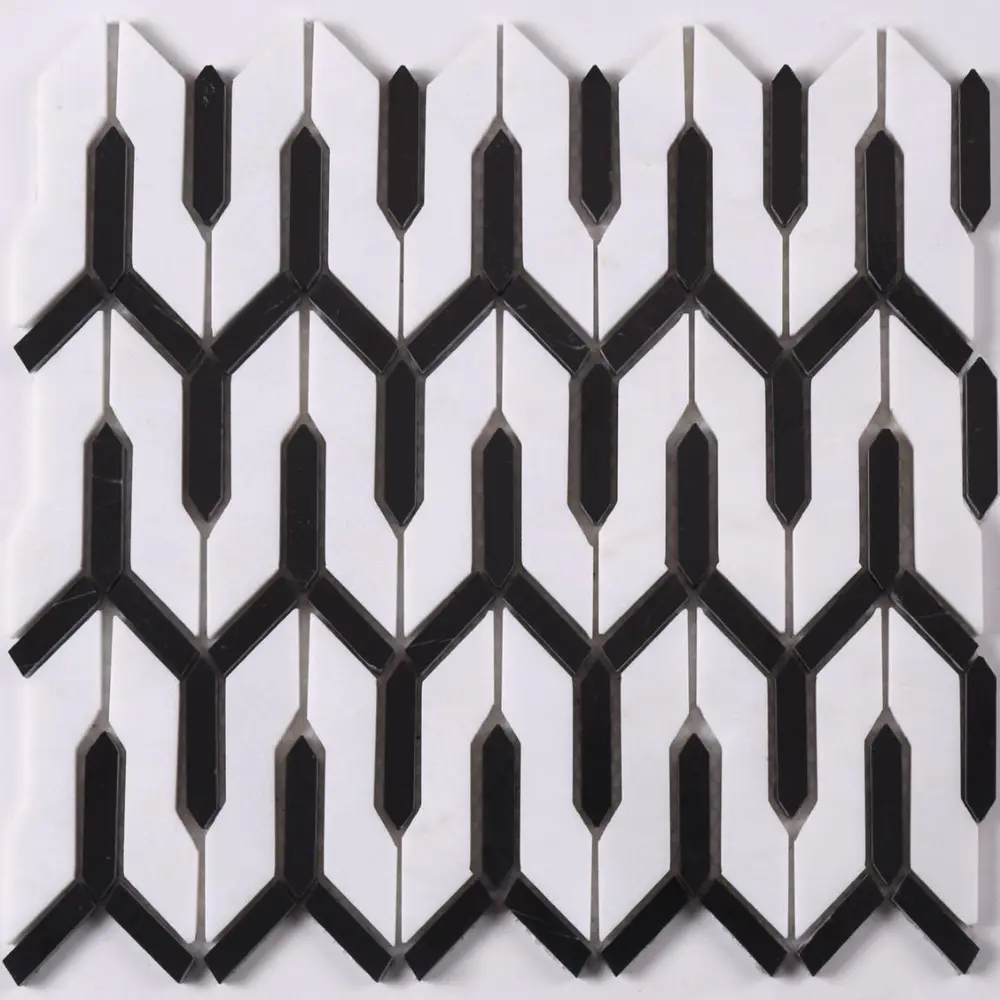

Glass Tile Mosaics

by:Heng Xing

2020-08-29

Sheeting involves the use of mosaic tile prearranged and glued on a paper, mesh, or movie sheet in order to facilitate a correct and lasting installation. Sheeting is completed by machine or by hand; the former could constrain sizes and capabilities.

To make sure the flattest and most uniform mosaic floor, installers lightly faucet the sheets with a wooden beating block and end hammer. This is particularly useful throughout sheets to degree and unify sheet transitions. For partitions, after about 15 to half-hour, the installers frivolously wet the face papers, preserving them wet with a moist sponge; this eventually causes the glue to release.

First, the installers gauge the thinset and clean out trowel strains, just as within the mosaic tile application. Generally, extra thinset is used as a result of these large tiles weigh greater than mosaic tile components. Unlike most mosaic applications, massive-format tiles require the use of spacers for uniformity of spacing. For mosaic installation with paper going through, installers frivolously faucet with a picket beating block and finish hammer and later lightly moist the face papers to launch the glue. Then the paper is peeled whereas the setting material is contemporary to permit for changes.

These blades have finer and more numerous diamonds and make a smooth cut through the glass and any backing with out chipping or tear-out that can be seen once the tile is installed. After marking the width of the tile, rigorously reduce with the specialised blade. Thin rips in massive-format glass tile such as this become fairly routine. The structure of the big-format glass tile in this bathe left a partial-width tile on the ceiling. That width varied barely as a result of the ceiling was barely out of degree.

Glass tile can be made with recycled bottle glass or other kinds of post-consumer and submit-industrial recycled glass material. The manufacturer can detail how salvaged glass is obtained, sorted, and used. Walking into a tile manufacturing facility illuminates a few of the time-honored strategies for making excessive-quality coloured glass pieces.

To make plumbing cuts for the bathe controls and for the piping that supplies the shower head, the method is similar to that with ceramic or porcelain. The difference is that extra care should be taken so that the glass breaks out evenly with out the utilized coating chipping out beyond the minimize. These cuts don’t need to be an ideal scribe to the pipe, but don’t assume that the plumbing flange will hide a nasty cut. The greatest, and possibly the one, way to make a clean and straight minimize down the size of a big-format glass tile is to make use of a moist noticed geared up with a specialized glass-chopping blade.

After this step, the installer applies the mosaic sheets to the thinset with light, even stress, the paper aspect away or toward the installer. Savvy set up teams periodically check the thinset for skinning, or slight drying, which requires removing and reapplication of the mortar cement.

At the identical time, one additionally sees how handcrafted processes and carefully guarded formulations work facet by side with modern automation and controls technologies. This refers to several types of manufacturing strategies, and every can produce a spread of unique visible and tactile effects, all produced at a range of temperatures from about 1,023 levels Fahrenheit to 1,599 levels Fahrenheit. Properly specified and manufactured glass tile surfaces are resilient and sturdy, providing a sustainable luxury finish utilizing recycled bottle glass. Explore sustainability attributes of glass tile, including the usage of recycled glass.

Custom message